Home »

Boilers and Air Preheaters

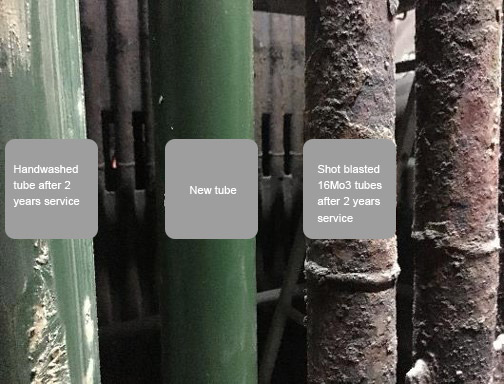

In many processes such as Waste to Energy and Biomass plants, combustion ashes are deposited on the tube’s external surface, leading to severe corrosion and a loss of efficiency.

When Tubacoat is applied to the external surface of boiler superheater or air preheater tubing, its anti-adherent and anti-corrosive properties, deliver the following important advantages:

- Increased efficiency; steam or air outlet conditions are optimized

- Higher plant availability; avoiding unplanned shutdowns and reducing maintenance

- Greater flexibility; allowing multi fuel burning

- Reduced emissions and operating costs

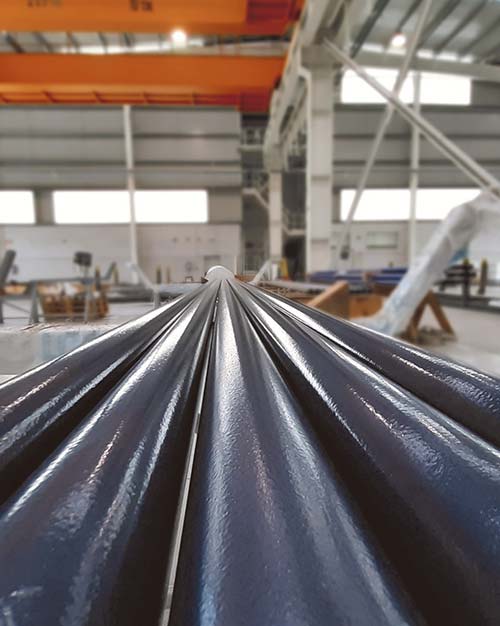

Steam superheater application:

Hot ash and corrosive gases shorten tubing’s lifespan

Tubacoat provides integral solutions, from single tubes to complete coils and waterwalls.