Home »

Heat Exchangers

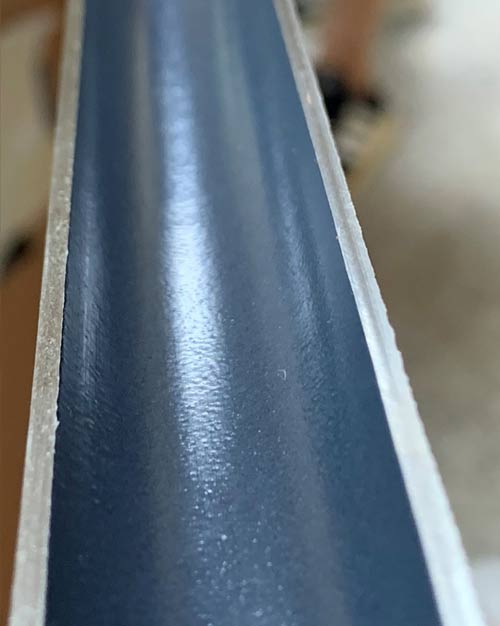

Fouling has been described as the major unresolved issue in heat transfer. Tubacoat significantly reduces fouling in the preheat train of Crude Distillation and Vacuum Distillation units, where optimum outlet temperature and pressure is critical to the process.

Fouling causes:

- Reduced heat transfer

- Increased pressure drop

- Higher CO2 emissions

- Frequent cleaning and hotspots

By applying Tubacoat to the inner surface of heat exchanger tubing operators obtain the following benefits:

- Increased heat transfer efficiency

- Reduced pressure drop

- Reduced CO2 emissions

- Less cleaning and extended service life